Testimonial: BETA MAX MC1600 Transport Platform at the West Point Museum

The BETA MAX MC1600 was key to the West Point Museum restoration, allowing safe, efficient material transport while meeting strict structural guidelines.

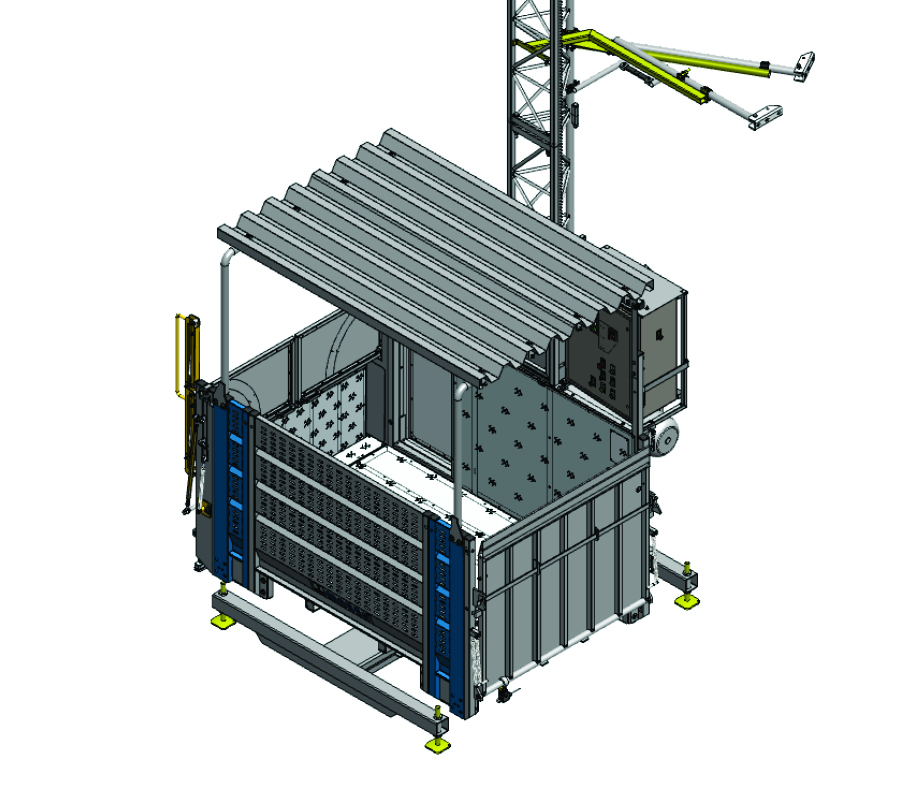

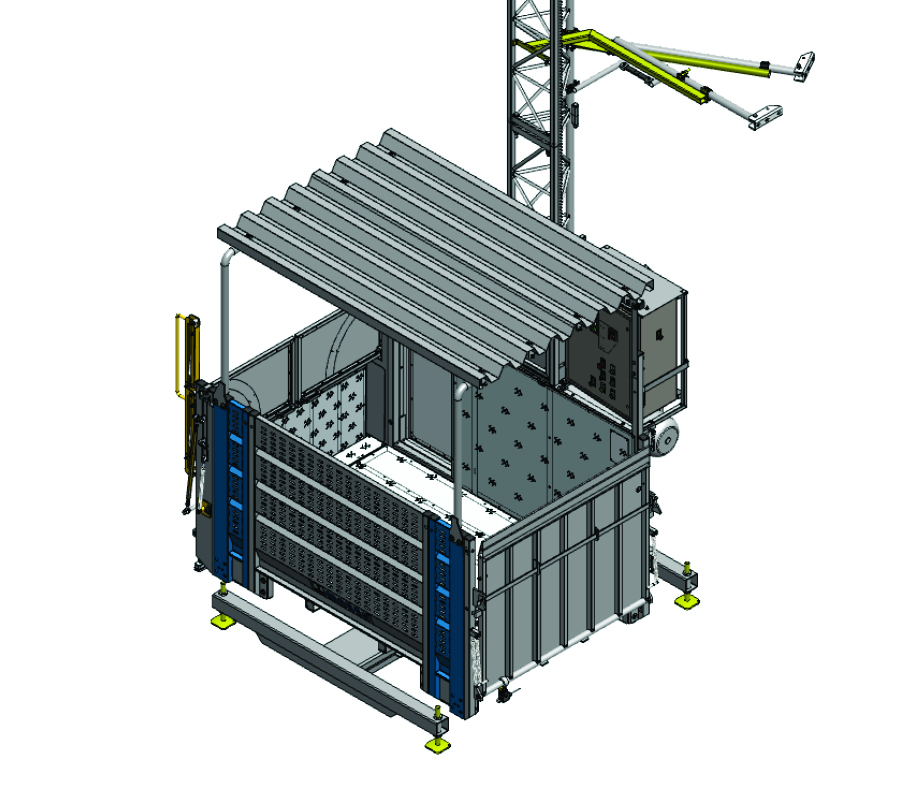

BETA MAX’s new MAX CLIMBER 2500TP/M MV is designed to deliver superior performance at a reduced cost, offering exceptional versatility and reliability on job sites. This model provides a powerful solution for material handling and personnel transport, meeting a variety of project needs.

BETA MAX’s new MAX CLIMBER 2500TP/M MV is designed to deliver superior performance at a reduced cost, offering exceptional versatility and reliability on job sites. This model provides a powerful solution for material handling and personnel transport, meeting a variety of project needs.

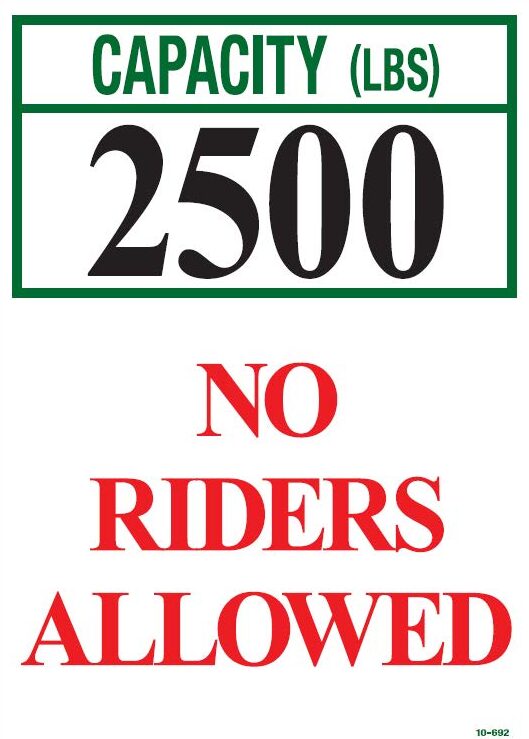

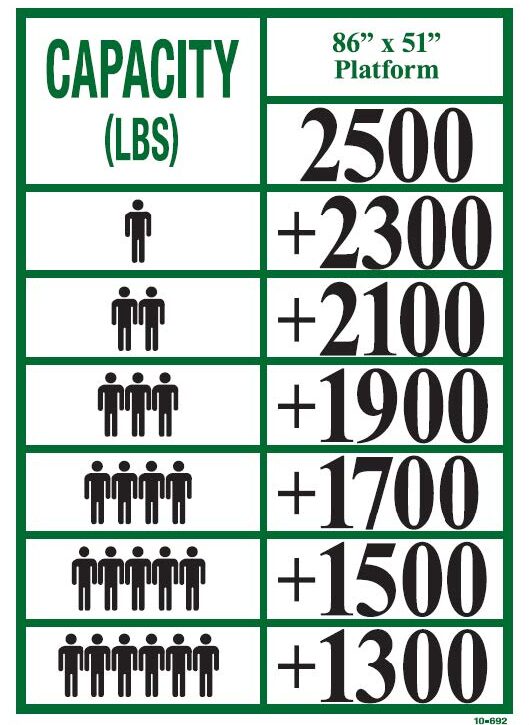

The MC2500TP/M MV offers impressive performance at roughly one-third the cost of traditional, larger hoists—making it an excellent choice for budget-conscious projects. It serves a dual purpose: it can be installed as either a material hoist or a transport platform. With a lifting capacity of 2,500lbs, it can handle heavy materials and multiple passengers with ease.

The MC2500TP/M MV operates at a speed of 80 feet per minute in material hoist mode and 40 feet per minute in transport platform mode, optimizing productivity whether you are moving equipment or personnel. Additionally, it is compatible with the MC2000PMB—our fully enclosed personnel & material construction hoist. Both systems now share many of the same parts, including the vertical mast and wall ties. This makes it easier to stock items for owners of both unit types.

Its enhanced VFD Controller provides Soft Start/Soft Stop functionality, which increases the efficiency of the motor and drive assemblies.

Designed with efficiency and ease of use in mind, the MC2500TP/M MV is simple to install and operate. It requires lower pull-out and downward forces, which makes it easier to tie into the structure with less impact. The built-in fold-out platform makes installing wall ties a straightforward process, allowing you to build as you go.

When installed as a material hoist, the MC2500TP/M MV has a compact footprint, needing just 106″ x 103″ of space. This small footprint makes it ideal for tight areas on busy job sites, while the basket dimensions of 87″ x 55″ provide ample room for materials, tools, and equipment.

The hoist also comes equipped with a unique open/close system for its unloading ramp. The exit door is equipped with a monitored locking solenoid, requiring the operator to acknowledge their intent to open the ramp, making loading and unloading of materials safer, faster, and more efficient.

The MC2500TP/M MV runs on A/C power: 3 Φ 208V, 45A, with a recommended 100A power supply service at the base of the unit. This ensures consistent, reliable performance across all operations. Additionally, the hoist’s easy-access electrical panels simplify maintenance, minimizing downtime and extending the life of the machine.

Built to withstand the elements, the fully galvanized loading and lifting unit provides excellent protection from harsh weather conditions, ensuring durability even in challenging environments.

Like all BETA MAX Hoists, the MC2500TP/M MV complies with industry safety standards, specifically ANSI/ASSP A10.5 and ANSI/SAIA A92.10, and it is cULus Listed– ensuring safe, reliable operation on any job site.

View the MC2500TP/M MV spec sheet here.

To discuss your project needs or get a quote, contact BETA MAX Hoists at (800) 644-6478 or info@betamaxhoist.com.

Stay up-to-date with the latest news and happenings at BETA MAX Hoists!

We use Mailchimp as our marketing platform. By clicking above to subscribe, you acknowledge that your information will be transferred to Mailchimp for processing. Learn more about Mailchimp’s privacy practices and Beta Max Inc.’s Privacy Policy.

You can unsubscribe at any time by clicking the link in the footer of our emails.

The BETA MAX MC1600 was key to the West Point Museum restoration, allowing safe, efficient material transport while meeting strict structural guidelines.

Quality Roofing Inc. used BETA MAX Hoists to replace a 32-story condo roof efficiently with minimal resident disruption.

Scaffold Resource utilized a Maxial Track Hoist and a MC2000PMB Personnel Hoist in their recent restoration work on the Cape Hatteras Lighthouse.

Efficiency in construction is crucial for completing projects on time, within budget, and with high quality. Key benefits include client satisfaction, cost savings, consistent quality, and a competitive advantage. BETA MAX Hoists enhance efficiency by accelerating material transport, reducing labor costs, improving safety, and offering versatile lifting options. These hoists streamline construction processes, leading to more efficient, safe, and cost-effective projects.