The hoist that changed the scaffold industry.

The safest and most efficient way to erect and dismantle scaffold.

The most widely used hoist for scaffolding for over 30 years.

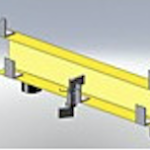

Base System: Motor and Controller, Pendant, Universal Carriage, Sliding Head, Top Stop and Bottom Stop.

Mounting Components: Track Sections, Kwik Bolts and Scaff-Clamps and Base Feet.

Carrying Accessories: Universal Platform, Frame Scaffold Carrier and Systems Scaffold Carrier.

100-3

Universal Platform

200-1

Universal Carriage

100-5

System Scaffold Basket

100-5

System Scaffold Basket

50-36

Pendant

100-2

Frame Scaffold Basket

30-40-5

Controller

80-1

Base Feet

80-2

Sliding Head

80-8

Movable Top Stop

90-4

Scaffold Clamps

90-6

Kwik Botts

80-4

Movable Bottom Stop

80-25-1

Motor

90-2

Aluminum Track-9'9" Length

90-1

Aliminum Track-6'6" Length

90-5

Aluminum Track-3'3" Length

Photo courtesy of V. Thornhill / Sunbelt Rentals