Standard Construction Hoist / Personnel Hoist (“Buck Hoist”)

Definition– Hoist that is installed inside or outside a building or structure during the construction, alteration, or demolition of the building or structure and that is used to raise and lower workers, other personnel, and materials which the hoist is designed to carry.

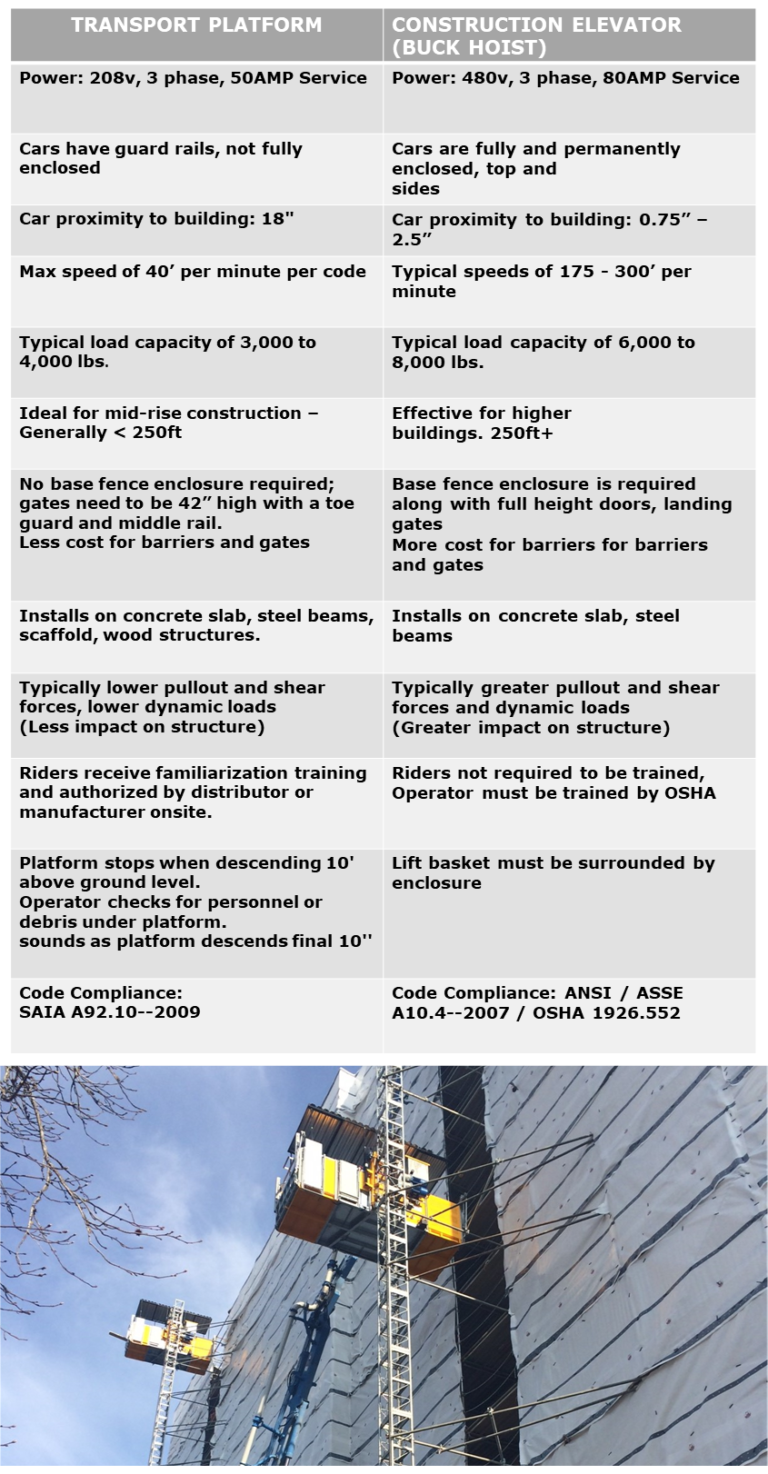

Generally, a buck hoist is needed to provide access to very high levels with travel speeds of up to 300 ft. per minute and lifting capacities in the 6000 lb to 8000 lb range. The traditional high speed construction hoist is most often found on high rise commercial construction and is an effective means of moving groups of people and materials from the ground to the top levels of very tall buildings.

Code Compliance: ANSI/ASSE A10.4-2007 / OSHA 1926.552

Transport Platforms

Definition –Tool of the trade designed for temporary installation on a building or structure, used to vertically transport authorized personnel, materials and necessary tools, to various access levels on the building or structure. This is not to be confused with a material hoist, personnel hoist / industrial elevator, or “buck hoist”.

Transport Platforms were designed for mid-rise construction and are usually found on commercial projects with heights of 250’ or less. These hoists are limited to a maximum travel speed of 40’ per minute with load capacities of up to around 4000lbs. Transport Platforms typically are more compact with a smaller footprint, they are less expensive than larger hoists, and are quicker and easier to install and operate. One primary feature of some Transport Platforms is that they have significantly less impact on the structure or building due to the lower dynamic loads and forces applied on the structure or building. This also makes transport platforms a popular choice for use on restoration, historical buildings, wood structures, etc. Transport platforms are primarily used for lifting personnel, drywall, sheetrock, cubes of brick, palletized and other large items.

Code Compliance: ANSI/SAIA A92.10-2009

KNOWING THE DIFFERENCE, AND HOW TO MAKE A SMART CHOICE

Understanding the specifications for the different machines and which projects they are best suited for may prove to be invaluable when estimating or planning. The proper equipment will increase efficiency and cost effectiveness and could be the difference between acquiring or losing a contract.

For example, generally you would not want to use a transport platform on a 350’ tall building because it would take way too much time to get to the desired height and would be inefficient. On the other hand, using a high-speed personnel hoist on a 10-story hospital building would probably be overkill and involve unnecessary costs.

It may not always be obvious which is the right machine for a specific application, but with careful consideration of the site limitations, building configuration and the requirements of the trade crews, the choice should become relatively clear, and using the right type of hoist for the job can have a significant positive impact on the overall outcome.

Bottom Line: Contractors have historically used the same type of personnel hoist or buck hoist for every job because they were unfamiliar with other options. For low and mid-rise construction, and projects where space is a premium, transport platforms are often less expensive, more efficient and productive alternative.